Steel Road Plates Things To Know Before You Get This

Steel plates are provide an excellent, momentary solution for covering unsafe holes on a construction site. These durable, durable plates permit roadways to return to service to ensure that building and construction can proceed. Here we discover the design information and ideal method installation advice. These plates can be used to make certain that roads can still be utilized whilst other stages of work proceed.

They provide an excellent concession for maintaining lanes, whilst work continues overnight and at weekends. They are frequently seen when excavations have started as a beginning of building and construction or fixing tasks. These plates are made to endure durable use on hectic roads. They feature an akti-skid finish and are available in a variety of colour finishes - Steel road plates.

The weights start from roughly 300kg and conventional road plates have a density of either inch or inch. The capacity to be bolted to the road.

Steel Road Plates for Beginners

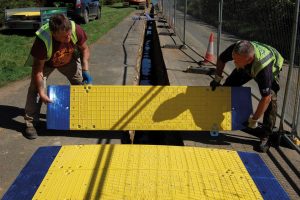

Hinged versions for fast access to the excavation or regular gain access to, e.g. driveways. Composite plates, which can suit numerous sizes of trench. Skid-resistance for boosted car, pedestrian and website worker security. Steel road layers can be mounted rather swiftly, but they are hefty. For this factor, they must be set up making use of a forklift or crane.

Check for variation by traffic packing from the start plates must always withstand displacement. Examine that the plates do absent a danger to any kind of kind of roadway individual and can be made use of by all roadway customers and lorry types, consisting of pedestrians, bicyclists and motorcyclists. Create a regular examination and maintenance to ensure that performance continues to be safe and maximum.

Fix home plates properly in any way times. Mechanical training ensures that home plates are set up accurately and securely. The right plates should be appropriate for the desired function Consider proper safety areas, particularly when preparing setup. The weight of home plates can cause swinging in the construction area or across adjoining carriageways/ footways.

If a ramp is created by the roadway plates, after that advising indications for pedestrian and road users are needed. Constantly a conduct complete website study, and take the expert suggestions of a structural designer.

The Ultimate Guide To Steel Road Plates

In order to boost safety, there are basics a variety of requirements and industry files directing their use in building and construction work zones. This post provides some highlights that may be handy in starting your examination. If you need extra details, please contact our specialist directly. Steel plates must be fixed in position to prevent activity.

The 7-Minute Rule for Steel Road Plates

In enhancement to being strongly touching the sidewalk, they need to be either pinned, recessed into the pavement, or secured with asphalt wedges around the perimeter. Pinning right into the sidewalk involves driving pins right into the pavements along the sides of the steel plates to avoid motion. Recessing entails removing the location where the steel plate will be put.

This leads to the steel plate being flush with the sidewalk. On top of that, when multiple steel plates are used and butt approximately each various other, they should be bonded together at the longitudinal seams. Steel plates can be really slippery, specifically when they are damp, unless they have an anti-skid finish applied.

Covering steel layers with a product that enhances rubbing helps motorcyclists and bicyclists retain control, particularly in wet weather condition. Problems which minimize sidewalk friction in work zones are of particular problem to motorcyclists and bikes. A common hazard in steel plate installations takes place when the user falls short to create effectively tapered ramps from the roadway to the sides of the steel plate( s).

How Steel Road Plates can Save You Time, Stress, and Money.

It positions a significant threat to motorcyclists and bicyclists that can quickly shed control when they speak to the abrupt/steep tapered ramp and the steel plate. Correctly tapered ramps allow customers to securely go across over the steel plates. Tapers for steel plates are typically created of asphalt. The taper sizes More Help differ from State to State and typically range from 20 to 1 to 120 to 1 (Steel road plates).

Division of Transportation's Federal Freeway Administration (FHWA) calls for that transverse pavement joints, which cause a bump, must be tapered at 60 to 1 (5 feet horizontal for every 1 inch of upright elevation difference). Select the proper size. Ensure ample overlap. Generally, steel plates need to expand at the very least one foot beyond the sidewalk opening onto company ground.

Not known Facts About Steel Road Plates

Welding is made use of when even more than one steel plate is used and they butt up to each other. Plates need to be countersunk when essential as a result of unequal streets. Plates must be coated with an anti-skid layer. The sides of the steel plates ought to be marked/painted to improve visibility. Appropriate advancement indication ought to be used.

His history consists of the construction, inspection, find out more.

These heavy-duty steel plates play a crucial role in boosting building and construction safety, providing temporary roadways, and ensuring smooth procedures on various task websites. As a building and construction devices provider, their value can not be overemphasized.

Comments on “The 7-Second Trick For Steel Road Plates”